Quest Industrial is continuously working to develop innovative robotic and automation products and systems that are lighter, easier to clean and more effective for the food industry. Don Wickstrum, President and Owner of Quest Industrial, gave a presentation where he stated, “We have spent more money in developing innovations than we made in profits each year since we opened, and have spent over a decade to bring them to market in an effective manner.” The robotic experts at Quest Industrial have developed several robotic solutions including specialized coating and protection system for robotic arms, direct food safe end of arm toolings or EOAT, and several innovations in robotic ultrasonic cutting and robotics processes in general. Mr. Wickstrum said, “Fanuc Robotic Arms coupled with our systems has made us the only company that has direct contact food lines for cheese from brine to warehousing which have been approved after installation by both the WDA and USDA.”

Furthermore, Quest’s specialists have designed several complete systems that are capable of operating in washdown environments.” The engineers at Quest provide unique robotic and automation solutions that are able to withstand the actual process solutions, as well as the washdown chemicals and procedures within a food plant, while holding up in the large temperature swings that many facilities experience. The ability to endure the tough requirements of food environments and increase food safety, Quest Industrial’s robotic coating takes the robots to an IP69 or better rating for protection against harsh environments. Quest’s coating greatly reduces the hazards of contamination that is found to happen with stock epoxies and paint.

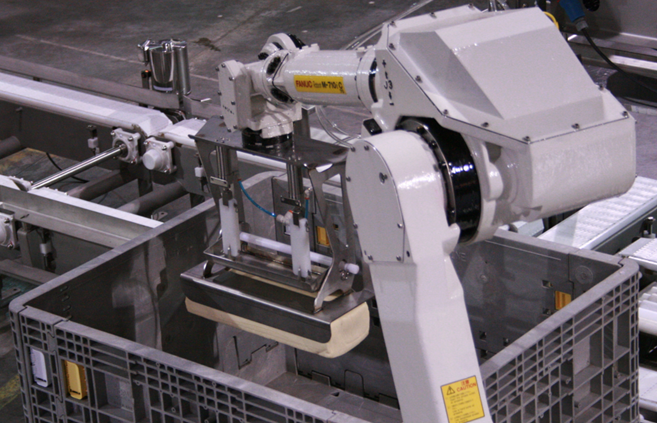

As stated previously, Quest Industrial’s robotic specialists have developed and are continuing to develop several innovations in Robotic End of Arm Tooling. Quest now offers several types of food safe tooling because of their vast experience working with the WDA, 3-A, and USDA has lead the engineers to develop tooling that is not only food safe, but is very reliable and easy to clean. One EOAT in particular, that is in operation, uses vacuum to pick the raw product with the use of no external vacuum sources, generators, or vacuum pumps – no holes or tubes to clean.

Additionally, Quest has created an Ultrasonic Cutting System for food that will tolerate the demands of the environment and process. Quest was able to design, over a 9 year time-span, a special tooling that allows the ultrasonic cutting technology to be coupled to the robot arm. The tooling has been accepted on site by WDA and USDA for direct cheese cutting applications. The cut from an ultrasonic blade leaves a remarkably clean cut with no chance of contamination, increasing shelf life and reducing fines.

One last item, not to forget, is how spectacular Fanuc vision really is – it allows our systems to not only track product, but also build in advanced quality measurements. Quest has been able to use vision to measure, qualify, and quantify product in a real time fashion that would otherwise need to be done with the use of additional labor or 3rd party systems. Quest Industrial has been able to capitalize on using Fanuc’s vision and has used it to its fullest potential.

Quest Industrial never stops innovating their innovations. In robotics and automation, there needs to be constant evaluating and developing of new and trusted technologies. As a robotic integrator, Quest strives to identify new challenges and hurdles that their customers face. Don Wickstrum stated, “We evaluate the companies’ directions and efficiencies to help develop and form the next innovation. We understand that what we have already developed and designed cannot be taken for granted.” He went on further to say that constant development is needed and that is something that Quest works to excel at – bringing at least one new product to market each year. Keep an eye on Quest Industrial as they continue to grow and develop new robotic and automated innovations and redesign their already unique robotic innovations.