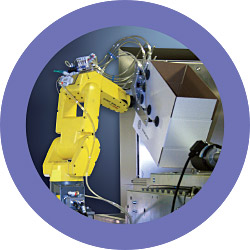

Quest Pro Pick Pack Automated Packaging Systems

Produce a Box, Pick the Product & Pack it Out!

The Quest PRO PICK PACK robotic automated packaging cell is designed with the end user in mind! It packs a 3-in-1 robotic automated system of erecting a box, picking and placing the product, and sealing the box into half the floor space of traditional machines with comparable capacities.

CUT floor space usage with the QUEST PRO PICK PACK robotic pick & place equipment!

Highlights of Quest’s Pro Pick Pack Automated Packaging Cell

- Half the floor space of traditional automated packaging machines with comparable capacities

- Erects and seals a box every 3 seconds

- Product in-feed rates at over 100 parts/minute

- Reconfiguration time is only 30 seconds

- Accepts a wide range of boxes with continuous change over from size to size allowing for virtually no interruption in production

- The best vision guided Fanuc robotics technology available

Standard Configurations of the Pro Pick Pack Automated Packaging Systems

- Case erector, product packing and case sealing 3-in-1 compact unit – versatile & fast

- Pick & Pack single or multiple products, and/or product types

- State-of-the-art light curtain safety features are used

- Automated visual verification of packing tools & placement

- Touchscreen operator interface making diagnostics easy

- Case erecting process reduces cardboard dust by 60%

- Operator’s manual and mechanical documentation built into the HMI

Pro Pick Pack Automated Packaging Cell Optimization

- Customized robotic tooling for your needs

- Automated visual inspection

- Product weight verification

- Divider insertion prior to packing

- Box accumulation to alleviate downtime

Cut the amount of floor space needed

to automate your facility.

Cut the amount of time product

change-over takes.

Cut the amount of overhead it

takes to make your products.

Specifications of the Pro Pick Pack Pick and Place Automation

Capacity – 50lbs/ unit of product

Construction

- 304 stainless steel formed and welded construction

- Constructed for incidental contact with water and a high-moisture environment

- Components have been selected with moisture considerations and sanitation in mind to minimize deterioration and maximize component service life

Dimensions

- Base of Pro Pick Pack: 150″L x 84″W x 136″H

*Electrical enclosures and stairwell are not included due to each having customizable placement to meet the user’s needs

Finish

- Raw stainless, polished, and matte finish

- FDA – compliant plastics

- Aluminum

- Cast metals finished with corrosion-resistant coatings

Weight Management – Case weight systems are available for integration into the conveyor system to output data values of tared weight, verified weight and/or gross weight

Speed – 22 pieces per minute with the option of packing multiples to increase cycle time

Controls – Allen-Bradley – consisting of PLC, Touch-Screen, HMI, Safety Systems & Sensors

Ease of Maintenance – Our machines are open and have full sensor and diagnostic features that come standard on the HMI

Choose Quest Industrial to Automate your Facility.