Fabrication & Installation

The Third Step…

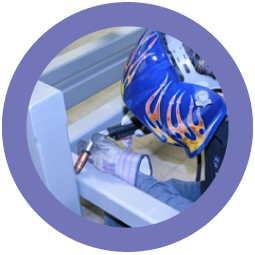

Fabrication

During the fabrication portion of the project , our specialists begin building your specially engineered and design equipment. These experts are detail oriented and know how important perfection is to not only you, but to our engineers who designed each piece of equipment. We also know that when equipment is built to perfection that the longevity of the cell is increased and we want your investment to stand the test of time.

Our specialists are trained in:

- Welding

- Laser Cutting

- Machining

- Assembly

- Pneumatic Components

- Electrical Components

- Safety Components

- Programming

- OHSA and NEMA Safety Standards

Once these processes are completed, we begin testing the product. We want to be certain that your equipment is working as expected at our facilities before it is installed at yours. During this phase, you and your team will be able to see your new automation equipment in action. It is at this time that we encourage you to discuss questions and concerns that may arise while watching. While we hope this is not the case, we want you to feel comfortable confiding in us. Next, we will make adjustments and tweaks to perfect your product then ship it to your facility.

Installation

Our experts stay involved during the installation process, ensuring that your system is not only built correctly, but also calibrated to exact specifications. Piece by piece you will see your robotic cell come together and we ensure that the equipment is installed in the proper location that will meet your needs and be the most efficient for your production goals. All of our customers see an increase in production almost immediately and many set records in their industry. The installation phase concludes with a complete test of the system so you can be confident it is running as intended. Next, we begin the training phase, which takes place during and after full production run-off.